Produit

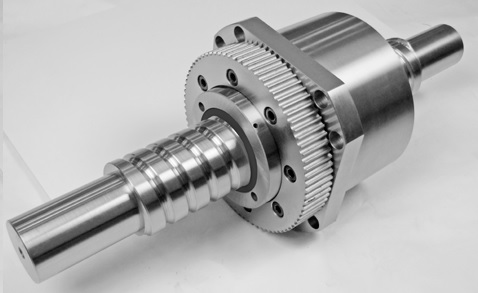

Ball screws with a driven nut

The ball screw with a driven nut is a construction unit designed for direct mounting into the support of the machine and for connection to the drive through a gearwheel, or a wheel for cogged belts. In the RMV variant readymade bearings are inserted between the nut and the housing, whilst in the RMI variant the bearing tracks are produced directly on the outer surface of the nut and the balls recirculate between the nut and the housing. The nut is preset for driving gearwheel mounting. The preloaded bearings have been selected with respect to the load-carrying capacity of the nut. The precision class of the bearings also complies with the precision class of the ball screw.

This compact unit is filled with a permanent grease filling and possible additional lubrication of the nut and the bearings is provided manually through a greasing hole, which can be adapted according to the requirements of the customer. This assembly is usually based on a double preloaded nut with segment recirculation system of the balls in a hole drilled lengthwise in the body of the nut above the thread. In the case of a double thread shaft the preload can be done by displacement of the run within each nut, resulting in an extremely compact unit for high speed and acceleration.

This solution provides machine tool builders with an opportunity to use an ecological and energy saving drive alternative in comparison with the standard shaft drive, which negatively influences the power consumption for its own rotation. It reflects the demands of the new European legislation being prepared in this regard.

Characteristics:

- Compact construction unit for direct drive of the nut

- Possibility of nut preload

- Standard geometric and working accuracy according to DIN ISO 3408

- Diameters from 50 to 80 mm

- Recommended pitch from 20 to 32 mm

- Precision class from IT1 to IT5

- Do×n = 100,000, efficiency 95–97% (according to the thread pitch and lubricant)

- Minimum strength of the shaft material Rm = 650MPa, functional surfaces of the shaft and nut hardened to 58–60HRC

- Working temperature -20 to +60°C

- Preloading by the difference between thread leads used in the two-start ball screws allows shortening of the nut

- Use of a single non-preloaded nut also allows shortening of the nut

- Machine tools

- Transporting mechanisms

- Substitution of racks

- Long actuation assemblies

Example of designation: RMV K50x25 – 4/ (driven nut with inserted bearings for ball screw with diameter 50 mm with pitch 25 mm and 4 working threads), or RMI K50×32 -4/ (driven nut with integrated bearings for ball screw with diameter of 50 mm with pitch 32 mm and 4 working threads).

Ball screws with a driven nut : www.ks-kurim.cz/en/ball-screws/ball-screws-with-a-driven-nut/